Billardy quality certifications for turning and cold forming

Partnership with local companies for the manufacture of turned and cold formed parts

Diversity and responsiveness are the watchwords of our business because we have come to work so closely with our local partners, particularly for surface treatments and heat treatments.

Because we use subcontractors located nearby, we can supply you with high-quality finished products within the required delivery times.

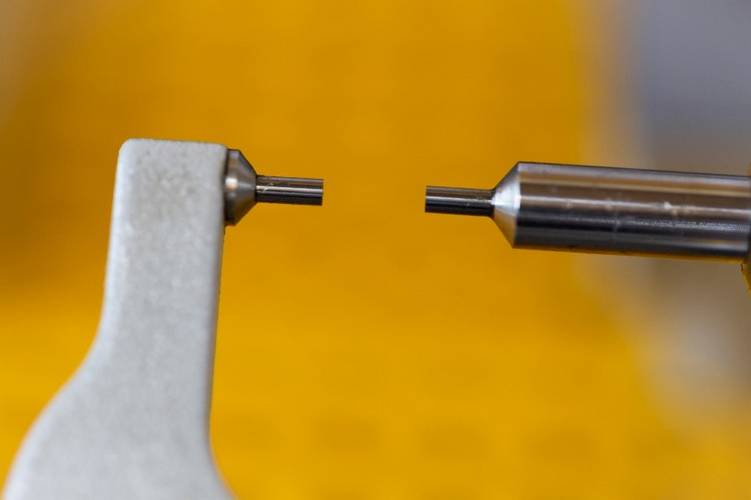

Quality control of parts manufactured by cold forming and turning

Inspection is performed at every stage of production to satisfy our customers’ demands in terms of quality and delivery times.

Our inspection facilities:

- profile projectors

- roughness testers

- hardness testers

- laser testing

- unit camera inspection via conveyor

- micrometers, stamps, rings, etc.

KEYENCE measuring instrument

The IMseries measuring instrument from KEYENCE can perform 2D measurements at a resolution of 0.2µm. Moreover, the scanning function can be used to measure relatively long parts. A precision fixturing base is used to place the parts in position on the platform. From these measurements, the device automatically generates inspection reports, which are archived on the company network.

Logistics for a global turning and cold forming service.

Logistics for a global turning and cold forming service.

With its professionalism and drive, the whole Billardy team is committed to providing total quality of service from design to delivery.

Our ambitions :

- To offer a global solution through our knowledge of turning, in synergy with cold forming.

- To offer the services of the local partners we have chosen for their skills.

- To interact with customers for a personalised service.

- To have a flexible production system to respond to all requirements.

- To constantly improve our services in order to adapt to changes in the market.

- To respond to price queries, the specific requirements of our customers, and the production and delivery deadlines imposed.

Washing machine for turned and cold formed parts.

Billardy takes care of our environment by using a 100% watertight washing machine. This means that no waste is discharged to the outside.

Its programmable interface allows the company to create different washing programmes according to customer specifications.

Inspecting the cleanliness of parts by granulometry and gravimetric analysis.